Integrated Design & Machining

Engineering-driven CNC machining and design support for low-volume, high-complexity parts.

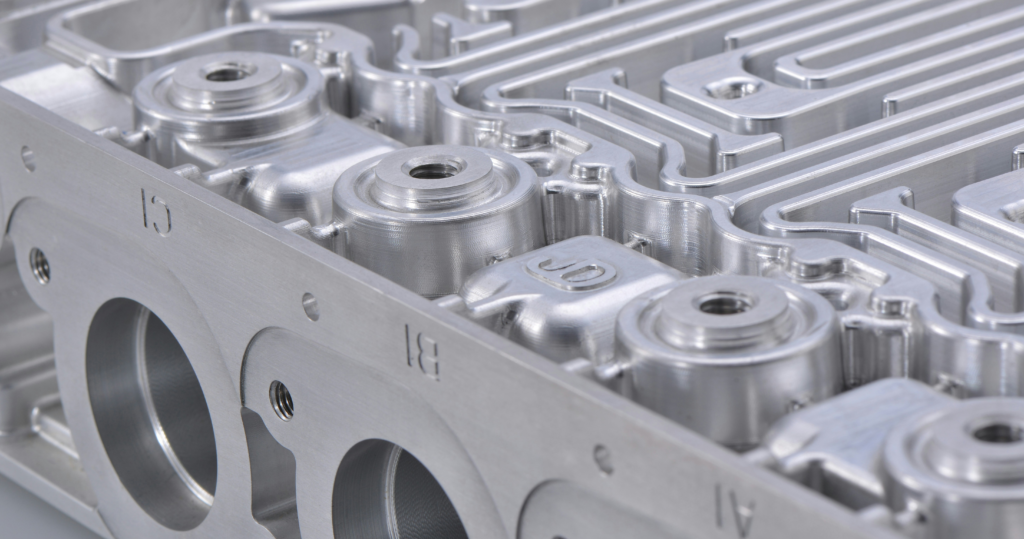

CNC Machining

Precision CNC machining planned with part function, tolerance, and downstream operations in mind rather than isolated toolpath optimization.

Design for Manufacturing

Design review and manufacturability assessment to identify risk early, reduce iteration, and ensure designs translate cleanly into machined parts.

Prototyping & Short Runs

Support for prototypes and short-run production where iteration speed, feedback, and alignment between design and execution are critical.

Integrated Process

Design, engineering, and machining are treated as a single workflow rather than disconnected steps. This integrated approach reduces handoff friction, uncovers issues earlier, and produces parts that better match design intent.

- Requirements Review

- Manufacturability Assessment

- CAM & Setup Planning

- Machining & Verification

- Delivery

In-House Capability

Design and machining is supported by multiple in-house platforms optimized for different classes of work, allowing the process to matched to the part instead of forcing all work through a single machine.

“If all you have is a hammer, everything is a nail.“

– A mindset we avoid

- Rigid CNC milling for precision components

- High resolution surface engraving and shallow-relief machining

- Accurate processing of thin stock and delicate parts

- PCB isolation routing and surface referenced machining

- 3 Dimensional scanning and reverse engineering of existing components

- Engineering driven CAM, inspection, and verification workflows